Long-distance pipelines

Long-distance pipelines carry natural gas from domestic production sites, underground gas storage facilities and the crossing points at the national borders to gas distribution companies, the in-take points of industrial consumers and the national borders of the country. They typically serve natural gas transmission in between large geographic regions and supply a number of delivery points.

The long-distance pipeline system in figures:

- Total length in Hungary: 5889 km

- Length of a single long-distance pipeline: 1–100 km

- Diameter: 80–1400 mm

- Nearly 400 independent underground pipelines

The pipelines are made of high-strength steel and feature corrosion protection.

Natural gas transmission in Hungary has a history of 70 years. The beginnings of natural gas transmission through long-distancepipelines are indicated by the transmission of crude oil and natural gas extracted in the crude oil fields of the Zala region to the Csepel refinery and Budapest. Oil and gas were carried between Bázakerettye and Budapest via DN 200 (200-mm diameter) pipelines, in intermittent operations in the years of 1949–1964. These pipelines were constructed in such excellent quality that certain sections are still operational today, though not as parts of the natural gas transmission system.

The total length of the Hungarian long-distance pipeline system is 5889 km. It means that if the individual pipelines were connected after one another, it would extend from Hungary to Mongolia. With respect to its volume, the pipeline system – when filled up to full pressure – can cover Hungary’s gas demand for one day in the coldest winter.

To provide natural gas continuously to the consumers, all the underground pipelines are covered with corrosion protection coating. This insulating layer prevents pipelines from becoming pierced or burst prematurely. The pipelines we operate have such a large combined surface area that if the coating of the entire long-distance pipeline system were spread out, it would cover an area that is one thousand times as large as the current stadium of Real Madrid.

For the even more effective corrosion protection of the long-distance pipelines, the subsurface pipeline sections are also safeguarded with the use of an active corrosion protection system from external power supply. In this technique, an external source of power is used to transfer protective current to the pipeline in a regulated manner, which prevents the pipeline from becoming pierced even under the harshest soil conditions. The protective equipment is located along the long-distance pipeline, at a distance determined considering the prevailing soil conditions. The data of the entire active (cathodic) corrosion protection system can be scanned via a wireless remote surveillance system in which the necessary supervisory control commands can be issued as well, making it unnecessary to travel to the distant locations.

Long-distance pipelines typically connect gas industry facilities that are at large distances from each other and therefore they are located in areas under the ground where they pose the least hazard or influence to human activities (agricultural cultivation). Therefore, in order to draw attention to the hazard posed by the pipelines running under the ground, route indicators are installed over the pipelines.

The route indicators carry information boards that show the toll-free number of our dispatcher service operated in 24/7. Consequently, any hazard can be reported directly to us.

The proper conditions of pipelines are ensured by means of rigorous and regular control inspections both during and after their construction in order to minimize the potential of faults and malfunctioning.

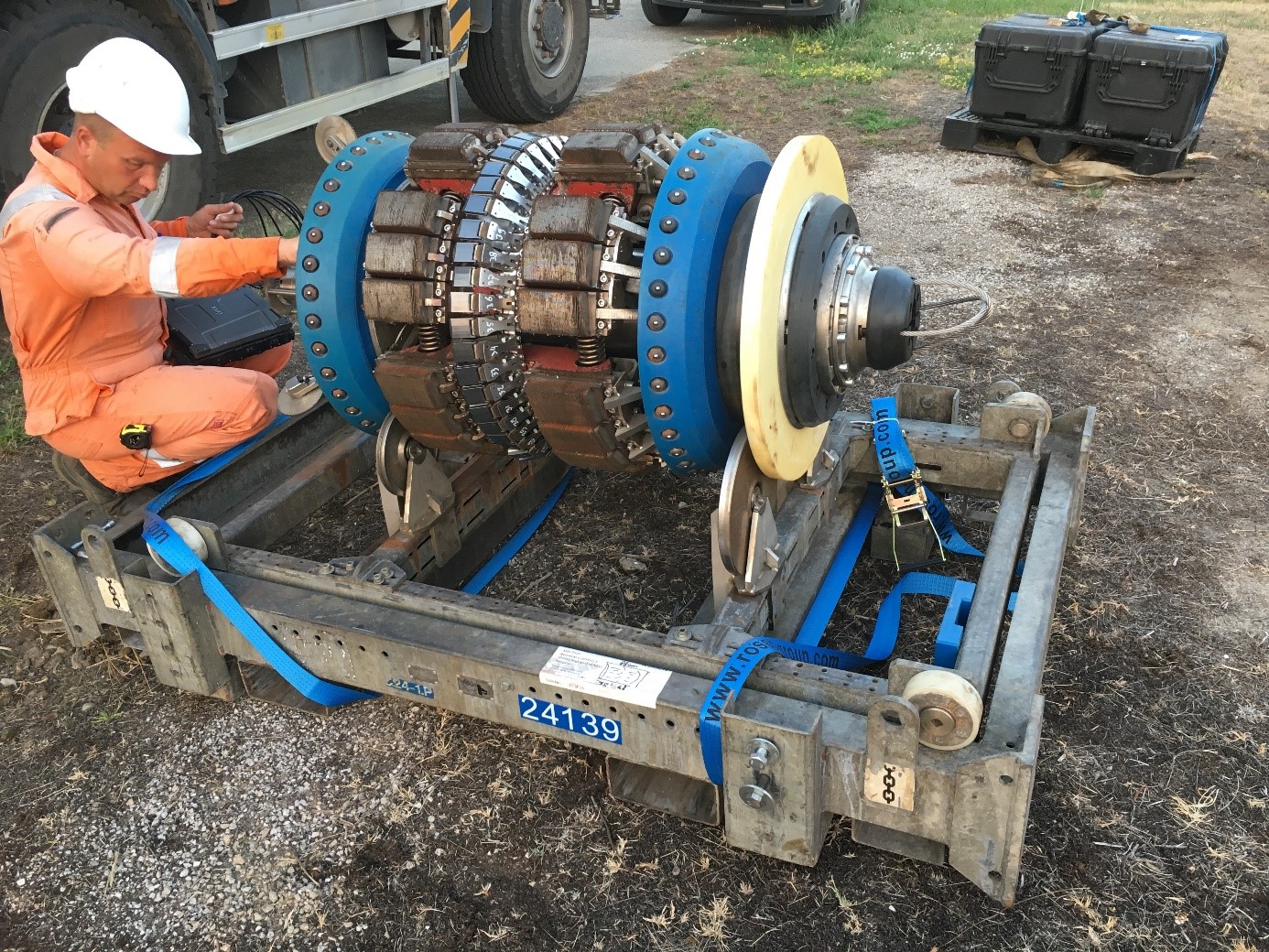

Such inspections are carried out with a state-of-the-art technique – called intelligent pigging – that is capable of detecting the smallest material loss, sized as a tip of a needle.

Intelligent pig used for the assessment of the pipeline conditions

This procedure is so unique and special that it has inspired even the creators of James Bond movies. In the movie titled The Living Daylights, the hero hid in a similar piece of equipment to flee from the territory of the former Soviet Union.

When compared with road and railway transport, carriage in pipelines involves the fewest accidents and for this reason transmission through long-distance pipelines can be regarded as the safest means of transport today.

Security

Security means both the consistent supply of natural gas and the safeguarding of the environment. In order to maintain security continuously, we regularly check and maintain our natural gas supply system.

Natural gas is carried in a gastight system of pipelines. Being subject to our continuous control, gas tightness ensures that no contamination with a detrimental effect on use can enter the pipeline system from the outside, whereas from the inside the explosive natural gas cannot be released, preventing any environmental pressure. Safe operating lifetime has increased to 80 years from a period of 30 years that was anticipated in the 1950s owing the improvement of the regulatory environment and technology.

In more details

Security means both the consistent supply of natural gas and the safeguarding of the environment. In order to maintain security continuously, we regularly check and maintain our natural gas supply system.

The natural gas transported in the long-distance pipelines is a potential source of hazard to the environment and therefore we make all efforts to minimize this risk. A safety zone has been designated within the surrounding of each pipeline with the following activities being prohibited within this zone:

- construction activities;

- the erection of all constructed structures;

- laying fires, burning materials;

- spilling, scattering corrosive and flammable materials that would jeopardize the conditions of long-distance pipelines;

- deposition, storage of materials;

Today the largest threat to our long-distance pipelines is posed by the earthworks carried out in the vicinity of pipelines without proper supervision during the growth of towns and cities.

You are kindly requested to contact us immediately if you have any plans drawn up affecting or crossing our long-distance pipelinets. In case a pipeline is damaged, the natural gas released to the air can potentially cause serious accidents and in addition a significant number of consumers may face the outage of services as a result of the fault, for the duration of repair works.

To avoid such accidents, the routes of our pipelines are marked with clearly visible posts.

Pipeline route indicating boards

These posts show the contact details of our dispatcher service operated 24/7. Should you experience any irregularity in the surroundings of our pipelines, please contact us immediately! Our toll-free number for fault reporting: +36 80 201 245.

The information board installed on the route and its data content.

As early as during the construction of pipelines and then later, during operation, we use the most modern methods of testing and control to supply natural gas to our consumers without interruption.

The routes of the completed and operating pipelines are regularly checked from airplanes, which is suitable for readily detecting illegal construction activities jeopardizing the pipelines, as well as any leakage that may occur along the pipelines, which triggers repair servicing operations.

The technical conditions of pipelines are checked with the available state-of-the-art testing devices at regular intervals. The equipment traveling along the pipelines during such inspections is capable of detecting faults sized as a tip of a needle.

Assessment of the pipeline conditions with the use of intelligent pigging

The evaluation of the inspection results allows us to plan the repair works on the faults that have been revealed on the pipelines. The only thing you may notice – typically in the summer season – is that for 2 days a year the operation of some of our pipelines is stopped for maintenance purposes. During this period, the main gas supply is suspended.